Technologies

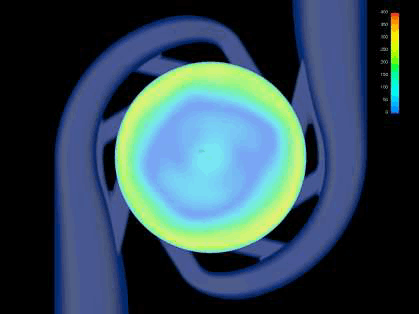

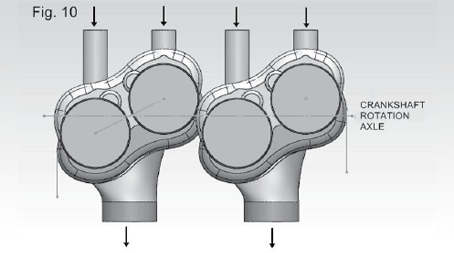

JLA - 1 MAP

Opposed Piston Internal Combustion Engine

30% Fuel efficiency, compared with same size traditional configurations.

30% More torque and power. Less emissions.

Multi fuel.

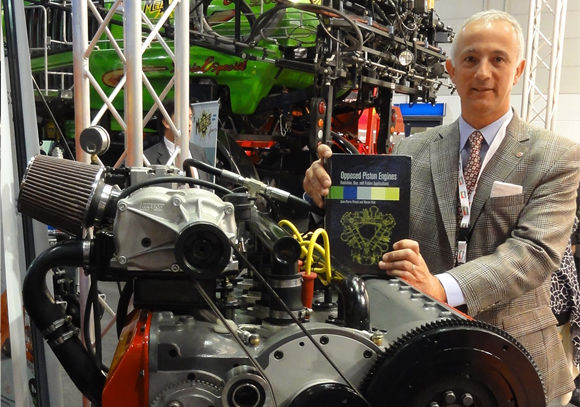

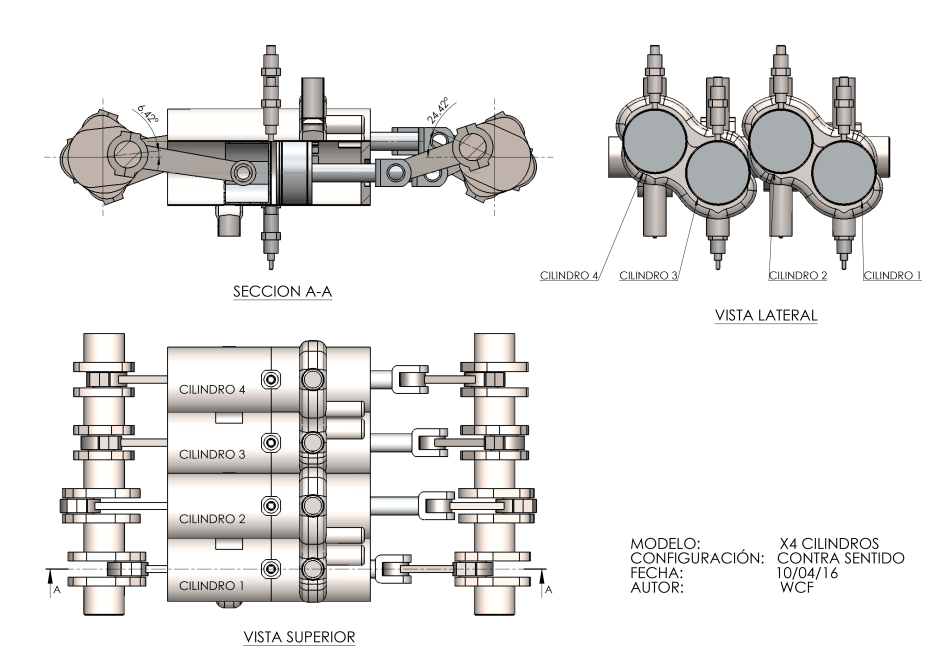

JLA - 2 MAP

Opposed Piston Internal Combustion Engine

30% size reduction for proper location in smaller vehicles.

30% Less moving parts.

More robust and reliable.

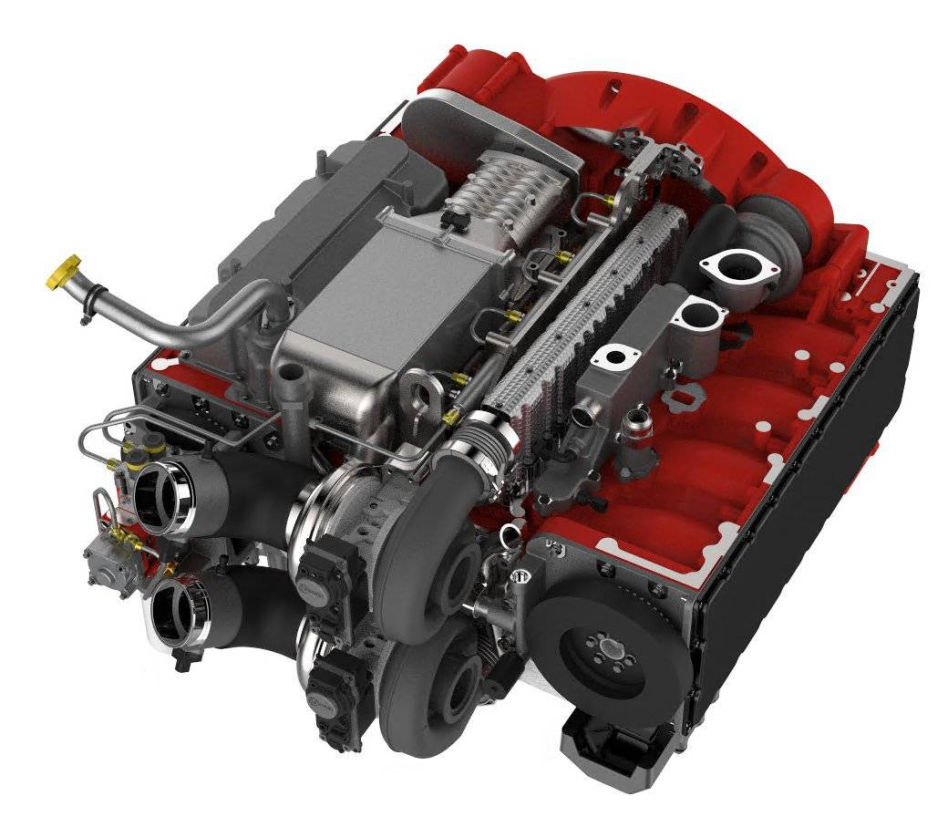

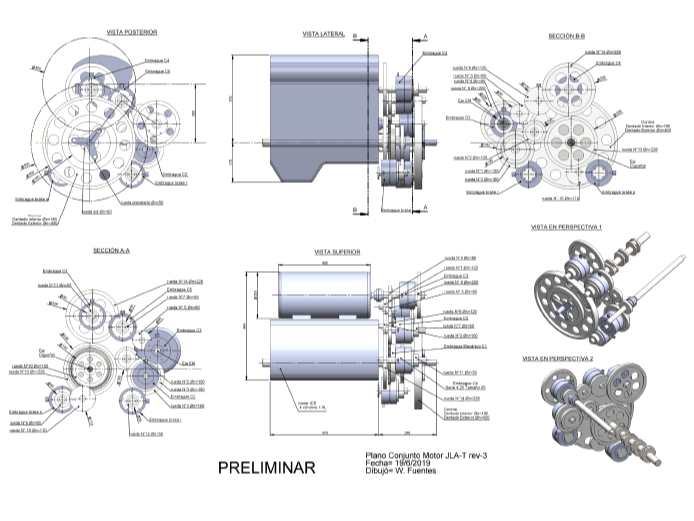

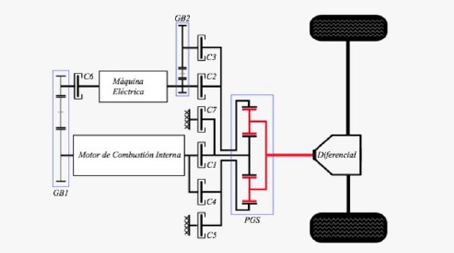

JLA - T MAP

Mild Hybrid Transmission System

47% fuel consumption reduction in 100% urban cycle.

Fits in any existing vehicle currently in use.